Degradable polymer matrices with antibacterial, antioxidant and anticarcinogenic properties

December 31, 2019

A new biomolecular strategy to improve bone regeneration

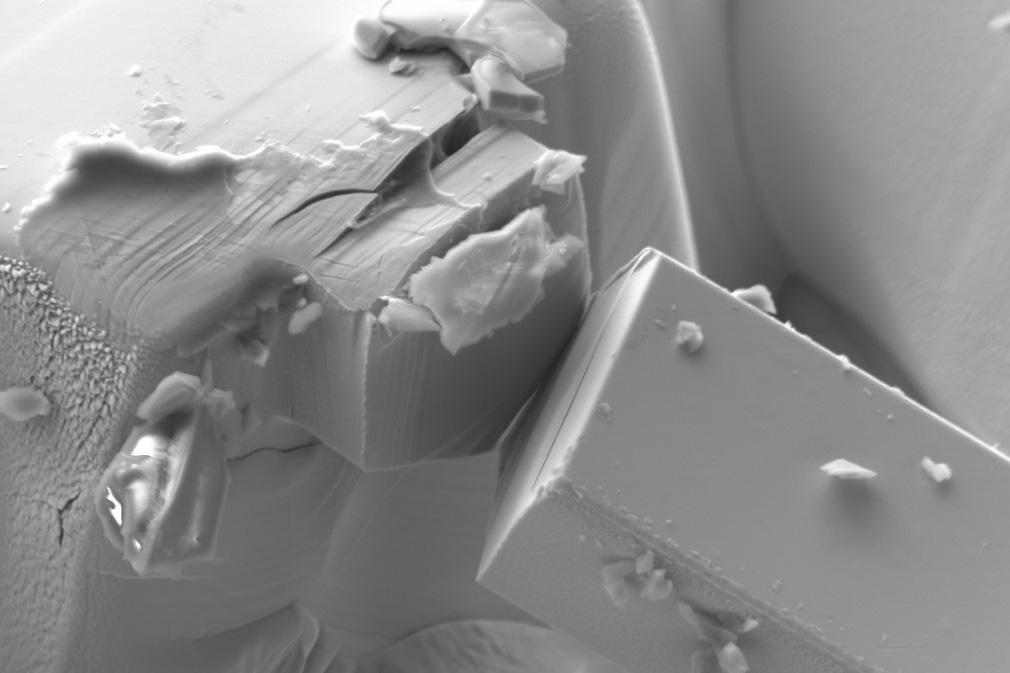

December 31, 2019The Center for Structural Integrity, Reliability and Micromechanics of Materials (CIEFMA UPC) is participating in the project MicroMech. This initiative is focused on developing new mechanical testing methodologies at small scale that involve the use of samples of very small dimensions (in the order of microns), mechanised using a focused ion beam microscope, and advanced characterisation techniques, such as nanoindentation and nanoscratching. The final objective is to assess micromechanical parameters in cemented carbides and in composite materials that are widely used in the manufacture of machine tools comprised of metal alloys and commonly known as “hard metals”.

The project includes characterising the mechanical behaviour of the two constituent phases of the hard metal: ceramic particles of WC and the cobalt-based metal binder, both of micrometric dimensions. In addition, the aim was to differentiate and understand the mechanical characteristics of the interfaces, both between WC and WC, and between the ceramic and metal phases in contact. To achieve this, one important challenge of the study is to machine microsamples of different geometries (beams and pillars) and sizes, but always under a few microns, by combining electron microscopy and focused ion beam microscopy techniques, the latter under different currents and conditions. Once the samples have been taken, their resistance to compression and fracture strength are assessed using a nanoindenter with nanometric resolution. From these tests, tensile, deformation and fracture data are obtained at microstructural scales, which are then used to optimise the microstructural design of these materials, using simulations and for the processing of new qualities of the material. These data will be used to assess different sources of errors and the reliability and reproducibility of these types of tests.

MicroMech is coordinated by the European Powder Metallurgy Association (EPMA), the technology centre CEIT and the National Physical Laboratory (United Kingdom). Other participants are the companies Hilti, Sec Tools, Ceratizit Sandvik Coromant and Kennametal. The project was completed in 2020.

Related Projects

- Researchers from the UPC are participating in the Quartz Enrichment Enabling Near-Zero Silicon (QUEEN) project, aimed at reducing the European Union’s dependence on external sources for critical raw materials, particularly metallurgical-grade silicon (MG-Si). To achieve this, the project proposes harnessing an underused resource: quartz sand from European quarries, to produce MG-Si locally, sustainably, and efficiently.

- A multidisciplinary team of researchers from the Research Group in Smart and Sustainable Resources and Industries (RIIS), the Sustainable Mining Research Group (GREMS), and the Construction Materials and Roads (MATCAR) group at the Universitat Politècnica de Catalunya – BarcelonaTech (UPC) is leading the VALORFIN project. The aim is to develop a technological solution for the valorisation of the fine fraction of construction and demolition waste (CDW), transforming it into new low-CO₂-emission cementitious materials, while also reducing the presence of hazardous materials in this waste.

- 08/07/2025Project Headerrightno-repeat;left top;;auto20px The research groups River Dynamics and Hydrological Engineering (FLUMEN) and Construction Materials and Roads (MATCAR) at the Universitat Politècnica de Catalunya – BarcelonaTech […]

- The Innovation in Materials and Molecular Engineering – Biomaterials for Regenerative Therapies (IMEM-BRT) research group at the Universitat Politècnica de Catalunya – BarcelonaTech (UPC), in collaboration with the Institute of Chemical Research of Catalonia (ICIQ), has developed polymer resins derived from plant-based materials to reduce the dependence of 3D printing on fossil fuel-based resins.