Five case studies in the Ciutat Vella neighbourhood on urban reuse and the promotion of innovative production models

May 26, 2021

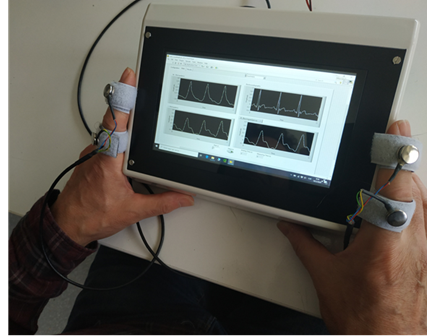

NICVA: A non-invasive device for fast cardiovascular condition assessment

June 10, 2021The Environmental Engineering (ENMA), group, which is a member of the Institute of Textile Research and Industrial Cooperation of Terrassa (INTEXTER), has coordinated ELDE, a project focused on the treatment of industrial effluents through technologies driven by electricity: electro-oxidation (EO), electrocoagulation (EC), addition of electrogenerated oxidants (EG) and electrodialysis (ED). To carry out the project, three industrial sectors were selected that are considered the most polluting: paper, chemical and tanning. The most problematic factor in wastewaters from these industries is the high organic load and presence of compounds that are not biodegradable.

For effluents from the chemical and tanning sectors, a flexible pilot (20 L/h) was constructed based on a combination of EO and EC techniques. This combination of techniques enabled a reduction of up to 70% in the organic content of the effluents, and fully eliminated the colour and turbidity. These technologies could also be applied to other industrial sectors.

In addition, an EC was constructed to treat 1 m3/h and was installed in a paper manufacturing company. The system is equipped with an efficient power source developed by the MCIA centre and solar panels to reduce the energy consumption of the treatment by between 60 and 100%, depending on the conductivity of the effluent. With the EC treatment, the organic matter was reduced by 25%, to obtain a treated effluent that could be reused in new production processes.

Finally, the environmental impact of using the selected electropurification techniques was assessed. In all cases, the carbon footprint was reduced by over 80% compared to the treatments that are currently in use.

The ELDE (Electrodepuration of industrial wastewater: technical, environmental and economic viability) project was co-funded by the EU European Regional Development Funds as part of the ERDF Operational Programme for Catalonia 2014–2020 with a budget of 1.7 million euros. Other participants in the project were the Motion Control and Industrial Applications (MCIA) for the UPC, and the Catalonia Institute for Energy Research (IREC), Eurecat and the SMEs Waterlogies, CIM Aigua and Lavola.

Related Projects

- A research team from the UPC, in collaboration with the company B. Braun Surgical, has created a ceramic and biocompatible catalyst that captures greenhouse gases and transforms them into useful chemical products in a more sustainable way and at a lower cost than current technologies. The technology has successfully passed the pilot phase through joint projects with companies from different sectors.

- The company Trace ID and the group Twin Investors, in collaboration with the Textile Technology research group (TECTEX), which is part of the Institute of Textile Research and Industrial Cooperation of Terrassa (INTEXTER) at the Universitat Politècnica de Catalunya - BarcelonaTech (UPC), are developing electronic devices to identify, monitor, and study the traceability of the products in which they are embedded.

- The Hydrogeology Group (GHS) at the Universitat Politècnica de Catalunya - BarcelonaTech (UPC) is participating in the LIFE REMAR project to develop an innovative and sustainable solution for the reuse of treated wastewater through infiltration, with the aim of increasing the availability of freshwater resources and improving the state of ecosystems.

- A team from the Environment Centre Laboratory (LCMA) of the Universitat Politècnica de Catalunya - BarcelonaTech (UPC) is taking part in a study commissioned by the city councils of la Llagosta, Mollet and Santa Perpètua (in Vallès Occidental), with the main objective of identifying the impact of industrial plants on the generation of unpleasant odours and continuously monitoring air quality in these municipalities.