CLIPE: Creating realistic and interactive virtual characters for VR/AR environments

December 16, 2025

Ciutat i Joc: A framework on game-based learning and storytelling to foster civic competences

January 14, 202618/12/2025

A research team from the UPC, in collaboration with the company B. Braun Surgical, has created a ceramic and biocompatible catalyst that captures greenhouse gases and transforms them into useful chemical products in a more sustainable way and at a lower cost than current technologies.

The technology has successfully passed the pilot phase through joint projects with companies from different sectors.

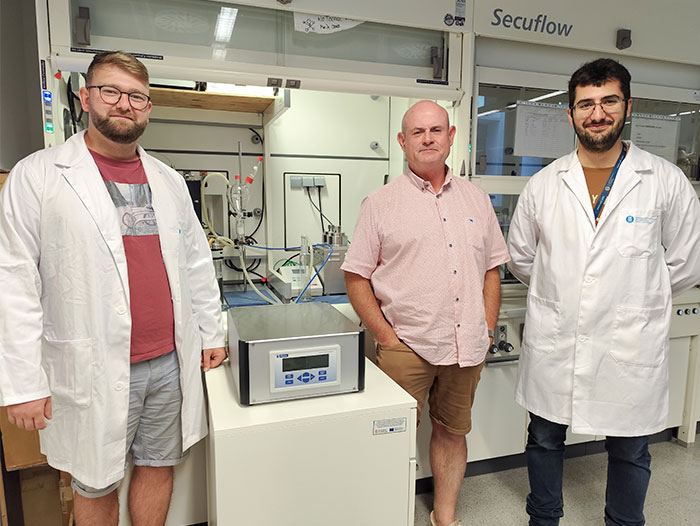

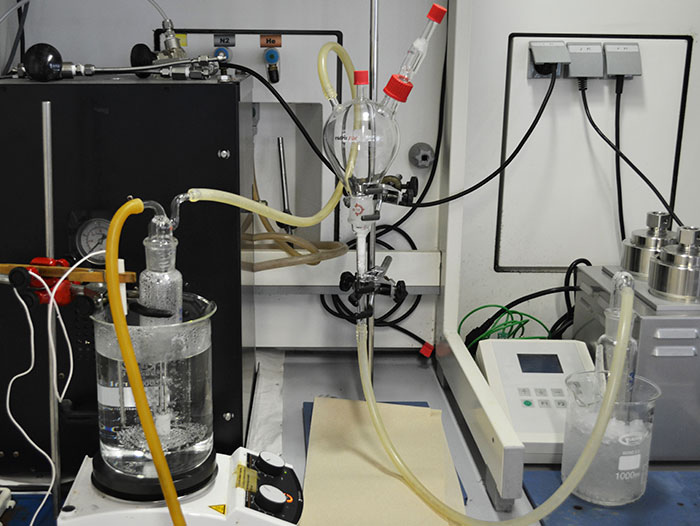

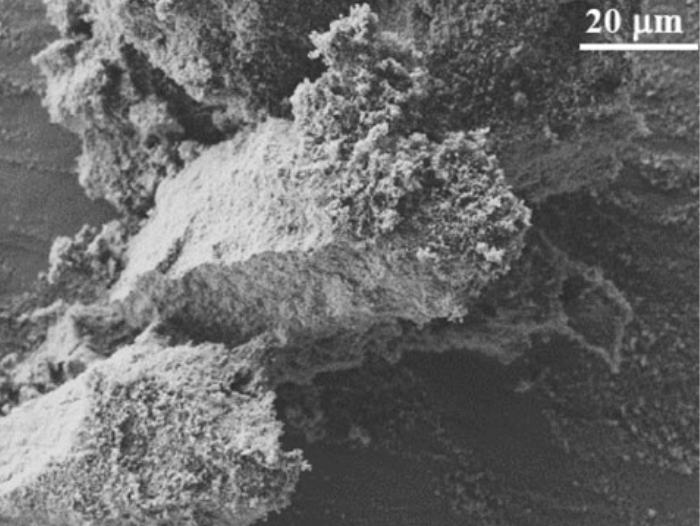

Researchers from the Innovation in Materials and Molecular Engineering - Biomaterials for Regenerative Therapies (IMEM-BRT) research group at the Universitat Politècnica de Catalunya (UPC), in collaboration with the R&D team of the company B. Braun Surgical, have developed a technology based on Permanently Polarised Hydroxyapatite, a ceramic and biocompatible material that acts as a catalyst. The main innovation lies in its ability to capture greenhouse gases, such as carbon dioxide (CO₂), and transform them into useful chemical products, such as ethanol or urea, in a more sustainable way and at a lower cost than existing technologies.

Carbon dioxide is considered the main cause of global warming and, therefore, reducing its emissions is both an academic challenge and a social necessity. The main problem, explains Sans, is that “it is a very stable molecule and, without a catalyst, a great deal of energy is required to break it. This means that, during the process, more CO₂ ends up being emitted than is actually reduced.” The challenge, therefore, is first to find a way to break this molecule and then to reorganise it so that other products of chemical or industrial interest can be generated and reintroduced into society.

Today, catalysts already exist that can capture and transform this gas, but they still require high pressures and extreme temperatures. In addition, they are made from noble metals such as gold or platinum, which are very expensive, often preventing this technology from being scaled up for industrial use. In contrast, the technology of Permanently Polarised Hydroxyapatitef is based on a material that is abundant in nature—hydroxyapatite, which is present in our bones. Thanks to its ability to absorb CO₂ emissions and its catalytic properties, it enables chemical reactions to take place under mild conditions: at atmospheric pressure and temperatures ranging from 9 °C to 150 °C. This technology is versatile and can be applied to industrial processes that generate significant CO₂ emissions. One example would be implementing the catalyst at the outlet of industrial chimneys in order to reduce direct emissions into the atmosphere while also recovering products such as ethanol, which can be used as a biofuel.

Impact

So far, the technology has been successfully tested at the Barcelona East School of Engineering (EEBE), on the Diagonal-Besòs Campus, and has passed the pilot phase in joint projects with major companies. One example is the Nuclis project, funded by ACCIÓ and coordinated by the company Aquambiente, Circular Economy Solutions S.L.U. (ACES), part of the Veolia Group, in which the use of the catalyst in an incineration plant in Mataró has enabled a 35% reduction in CO₂ emissions. Another case involved the high conversion of this gas into different products, developed jointly with the company VISCOFAN.

The catalyst developed within the framework of the project is affordable and has no environmental impact, which could transform the way companies manage gaseous waste, allowing them to reduce their carbon footprint while at the same time generating economic value.

The project has received the 15th UPC Research Valorisation Award, by the Social Council with the support of Fractus and the Fractus UPC Deep Tech Hub, as the best market-applied invention.

Sector

Topic

You want to know more?

Related Projects

- The Visualisation, Virtual Reality and Graphic Interaction Research Group (ViRVIG) at the Universitat Politècnica de Catalunya - BarcelonaTech (UPC) has participated in the XR4ED project, an initiative that connects the educational technology (EdTech) and Extended Reality (XR) sectors, with the aim of transforming learning and training across Europe.

- The inLab FIB at the UPC has collaborated with Lizcore® for the development of a proof of concept based on artificial intelligence to improve safety in climbing with autobelay devices. The system allows the automatic and accurate detection of risk situations before starting a route.

- Researchers from the Centre for Image and Multimedia Technology of the UPC (CITM) and from the DiCode research group (Digital Culture and Creative Technologies Research Group) of the Universitat Politècnica de Catalunya – BarcelonaTech (UPC) have worked on the project The Eyes of History, an initiative of the Catalan Agency for Cultural Heritage that offers an immersive view of Catalan cultural heritage. It is especially aimed at the first and second cycles of secondary education and was created to bring heritage into the classroom. Its goal is to bring the history and monuments of Catalonia closer in a vivid and innovative way, using tools such as virtual reality and new museographic narratives.

- City and Play is a social action project coordinated by researchers from the Centre for Image and Multimedia Technology (CITM) and the DiCode research group (Digital Culture and Creative Technologies Research Group) of the Universitat Politècnica de Catalunya – BarcelonaTech (UPC), the Universitat Oberta de Catalunya (UOC) and the University of Barcelona (UB), and funded by Barcelona City Council. The aim of the project is to promote civic competences and reflection on the urban environment among adolescents through the creation of an open framework that uses methodologies based on play, co-creation and storytelling.