Exoskeletons that can reduce by 60% the muscle effort of employees in the automobile sector

February 14, 2019

Best Routes: Improvements in routes and distribution of food products

March 4, 2019INTEXTER and Motion Control Applications (MCIA UPC) are participating in the REGIREU (Research on water regeneration technologies and risk management for reuse) project, which is designed to gain knowledge and develop innovative technologies to reclaim residual urban and industrial wastewater for subsequent reuse.

One of the project activities is carried out in INTEXTER’s Laboratory of Control of Environmental Contamination and is coordinated by the researchers Mercè Vilaseca and Víctor López. They will assess at pilot scale the combination of two treatment technologies: Moving Bed Biofilm Reactor (MBBR), in which organic matter in water is broken down with the biomass adhered to carrier media that move slightly, and Membrane Bioreactor (MBR) technology, which separates sludge by membrane filtration.

MBBR technology consists of a biological treatment for wastewater with high pollutant loads. The advantages of this method over standard activated sludge treatments are improved oxygen transfer and shorter retention times. In addition, the treatment supports higher organic loads.

MBR technology is based on a biological treatment with suspended biomass to treat wastewater. The biomass is separated from the water through a membrane filtration system instead of decantation. The advantages over activated sludge systems are a smaller carbon footprint, higher quality effluent, good disinfection capacity and the capacity to support a higher volumetric load. In addition, treatment plants require less space.

INTEXTER researchers state that “a mixed technique using both technologies could be very effective to treat wastewater from the textile industry and reuse the effluent in new dyeing processes”. For the REGIREU project, a pilot plant has been designed and built that combines MBBR and MBR to obtain high quality effluent (low organic load, a lower quantity of suspended solids and cleaner) that is suitable for reuse in textile dyeing processes.

In this activity, INTEXTER collaborates with an SME for water treatment, BIOFIL; a textile company, Acabats del Bages; and Eurecat-CTM. The project has a total budget of 2.2 million euros and is developed within the framework of the RIS3CAT Community of Water and the European Union with the European Regional Development Fund (ERDF).

Related Projects

- A research team from the UPC, in collaboration with the company B. Braun Surgical, has created a ceramic and biocompatible catalyst that captures greenhouse gases and transforms them into useful chemical products in a more sustainable way and at a lower cost than current technologies. The technology has successfully passed the pilot phase through joint projects with companies from different sectors.

- The company Trace ID and the group Twin Investors, in collaboration with the Textile Technology research group (TECTEX), which is part of the Institute of Textile Research and Industrial Cooperation of Terrassa (INTEXTER) at the Universitat Politècnica de Catalunya - BarcelonaTech (UPC), are developing electronic devices to identify, monitor, and study the traceability of the products in which they are embedded.

- The Hydrogeology Group (GHS) at the Universitat Politècnica de Catalunya - BarcelonaTech (UPC) is participating in the LIFE REMAR project to develop an innovative and sustainable solution for the reuse of treated wastewater through infiltration, with the aim of increasing the availability of freshwater resources and improving the state of ecosystems.

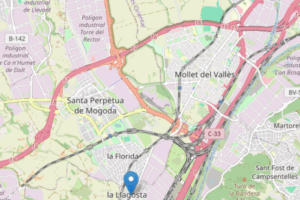

- A team from the Environment Centre Laboratory (LCMA) of the Universitat Politècnica de Catalunya - BarcelonaTech (UPC) is taking part in a study commissioned by the city councils of la Llagosta, Mollet and Santa Perpètua (in Vallès Occidental), with the main objective of identifying the impact of industrial plants on the generation of unpleasant odours and continuously monitoring air quality in these municipalities.