FIREPRIME: Tools and Services to Improve Wildfire Safety and Prevention in Europe

May 20, 2025

WhATTer: Green hydrogen from wastewater: energy and water circularity in the textile industry

May 30, 202523/05/2025

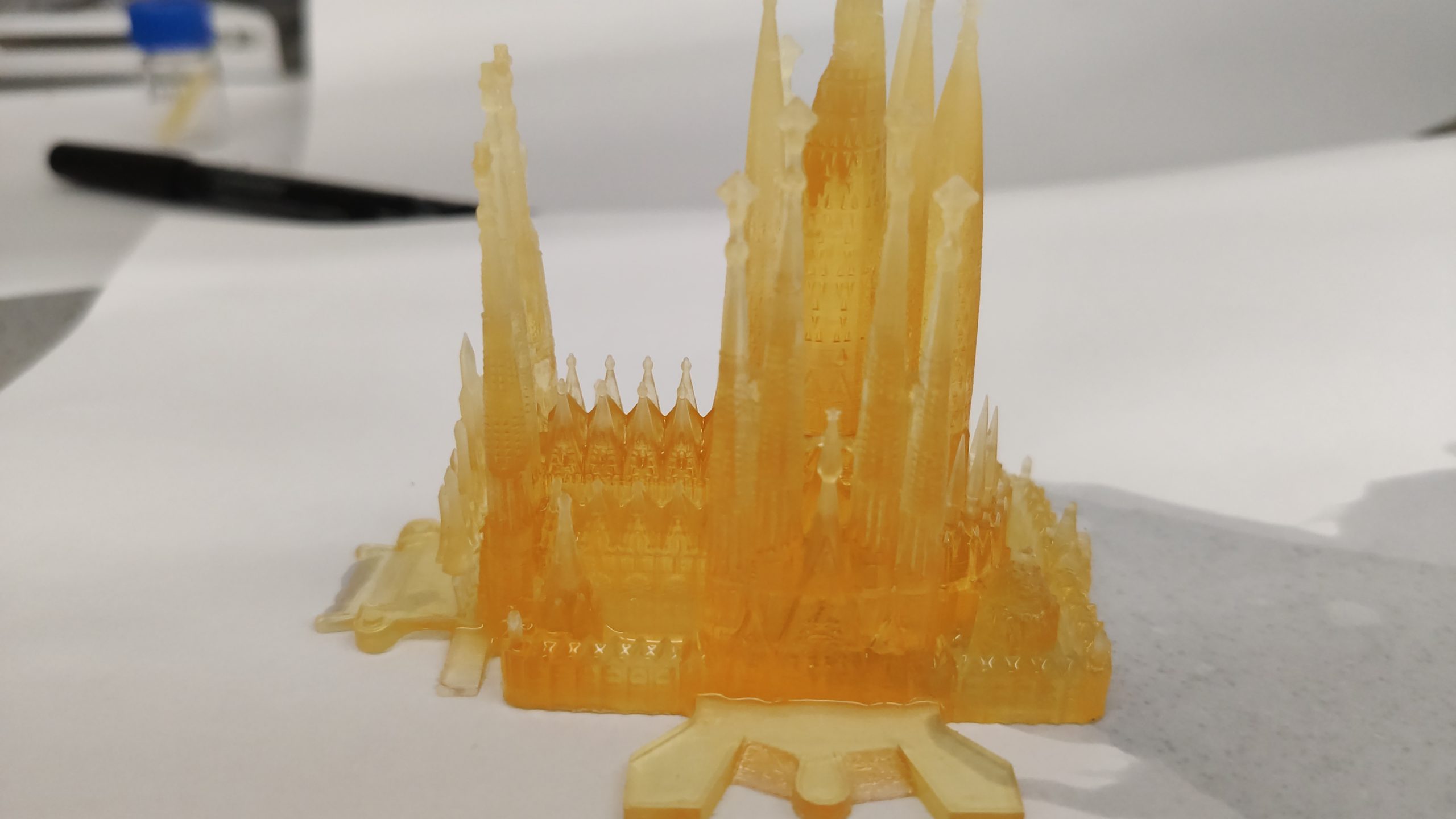

The Innovation in Materials and Molecular Engineering – Biomaterials for Regenerative Therapies (IMEM-BRT) research group at the Universitat Politècnica de Catalunya – BarcelonaTech (UPC), in collaboration with the Institute of Chemical Research of Catalonia (ICIQ), has developed polymer resins derived from plant-based materials to reduce the dependence of 3D printing on fossil fuel-based resins.

The 3D printing industry is currently undergoing a key transformation towards more sustainable and environmentally responsible production models. One of the main challenges is to replace widely used fossil-based resins with renewable alternatives that maintain the technical performance required for light-based printing processes, such as rapid photopolymerisation with good mechanical stability of printed prototypes.

Polymeric resins have been among the most commonly used materials since the early days of 3D printing, especially in technologies that use light to solidify them, such as digital light processing (DLP) printing techniques. These resins are formed from liquid compounds, called monomers and oligomers, which become solid through polymerisation under ultraviolet (UV) or visible (vis) light. While other 3D printing techniques, such as Fused Deposition Modelling (FDM), already use more sustainable materials like PLA (made from corn starch), replacing the starting materials in DLP printing is more challenging. Producing resins with natural components is complex, as these raw materials must support polymerisation reactions (the chemical process that turns them into plastic) in a liquid, solvent-free state.

In this context, new 3D polymer resins have been developed using monomers sourced from various natural origins, such as succinic acid, malic acid, and tartaric acid, which can be found in foods like corn, broccoli, apples, and grapes. The aim of the project is to promote additive manufacturing technologies through a process of technological maturation and to foster the implementation of this technology within the Catalan plastic prototype manufacturing industry.

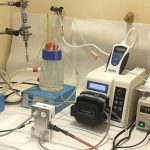

The research was conducted in two phases. In the first phase, led by IMEM-BRT, the polymer resin was prepared using plant-based materials suitable for 3D printing. Subsequently, the ICIQ's Knowledge and Technology Transfer and Industrial Projects division (ICIQ-KTT) carried out the printing of the resin.

For light-based 3D printing, liquid, solvent-free resins with good polymerisation kinetics (i.e. how fast the polymerisation reaction occurs and what chemical steps are involved) are required to ensure industrial viability. These monomers enable the synthesis of functional resins in a single step, which can be used in digital light processing (DLP) or stereolithography (SLA) printers.

Using this approach, the researchers were able to produce resins containing up to 50% plant-based content, and the printed parts demonstrated good structural stability and a high rate of biodegradability. However, to ensure the necessary polymerisation properties and mechanical stability, it was necessary to combine these natural components with petroleum-derived co-monomers. Some early formulations, particularly those based on malic and tartaric acids, exhibited thermal fragility. For this reason, the team opted to focus on more robust combinations, prioritising the use of succinic acid.

Impact

This initiative contributes to the transition towards a circular, low-carbon economy by reducing the use of fossil resources and promoting the use of renewable raw materials in the additive manufacturing sector. The developed resins offer a viable alternative for producing 3D parts with suitable properties for industrial, medical, and educational applications, thereby supporting the adoption of eco-friendly solutions in real-world settings.

Partners and Funding

This is the second type of polymer resin developed by ICIQ and UPC within the Base3D project, under the Light3D cluster, led by LEITAT. The first was a biodegradable polymer that enabled high-performance printing using DLP printers.

The IMEM-BRT group is part of the UPC’s Centre for Research in Multiscale Science and Engineering (CCEM), which is recognised as a María de Maeztu Unit of Excellence. The group currently operates a 3D printing laboratory equipped with printers for Fused Deposition Modelling (FDM), hydrogel and bio-ink extrusion, and resin polymerisation using UV light curing at adjustable wavelengths of 365 nm, 395 nm, and 405 nm.

The project was part of the Base-3D Project (001-P-001646), led by CIM UPC and co-funded by the European Regional Development Fund (ERDF) under the Catalonia ERDF Operational Programme 2014–2020. It had a budget of €3,774,442.41 and ran for 36 months (2020–2022).

Sector

Topic

You want to know more?

Related Projects

- The Centre of Technological Innovation in Power Electronics and Drives (CITCEA) of the Universitat Politècnica de Catalunya - BarcelonaTech (UPC) is leading a European project that redesigns the current energy system to stabilise the power grid in the face of high renewable energy penetration. The proposed solutions involve using the loads that consume energy to help balance the grid.

- A team from the Environment Centre Laboratory (LCMA) of the Universitat Politècnica de Catalunya - BarcelonaTech (UPC) is taking part in a study commissioned by the city councils of la Llagosta, Mollet and Santa Perpètua (in Vallès Occidental), with the main objective of identifying the impact of industrial plants on the generation of unpleasant odours and continuously monitoring air quality in these municipalities.

- Researchers from the Concrete Sustainability and Smart Structures (C3S) research group, part of the Construction Engineering (EC) group at the Universitat Politècnica de Catalunya - BarcelonaTech (UPC), are leading the CIRC-BOOST project, which aims to promote sustainability, industrial competitiveness and greater resource efficiency in the European construction sector.

- A research team involving the Barcelona Innovative Transportation (BIT), inLab FIB, CARNET Barcelona – Future Mobility Research Hub (CER-AMA), and the Department of Computer Architecture (DAC) of the Universitat Politècnica de Catalunya - BarcelonaTech (UPC) is driving the i-MovE project, which aims to incorporate multisectoral data to provide much more accurate and valuable information for the mobility sector. The project develops four use cases focused on both companies and mobility authorities, covering public and individual transport, using the UPCxels demonstrator.